Fire sprinkler systems are used to protect buildings, equipment, and other property from devastating damage. However, in occasional cases of extreme weather and/or misuse, these systems can actually cause damage due to the unintentional release of water. Most properties utilize wet pipe systems as the primary means of fire suppression. The National Fire Protection Association (NFPA) Standard 13 for the Installation of Sprinkler Systems requires wet pipe fire sprinkler systems to be protected from freezing temperatures by installing the systems within areas that can be reliably maintained above 40° Fahrenheit (installed within the building thermal envelope). When a breach exists within the thermal envelope, or the thermal envelope is improperly constructed or modified, water within sprinkler systems can freeze during very cold weather; causing pipe ruptures, broken fittings, or broken sprinklers.

Figure 1. Fractured grooved pipe coupling

Figure 2. Broken malleable iron threaded 90° ell fitting and pipe

Dry pipe systems are a type of sprinkler system used in areas expected to be exposed to freezing temperatures, such as loading docks, warehouses, and unconditioned attic spaces. These systems must be installed with a positive and uniform slope to drain, and the piping must be maintained in a dry state. Auxiliary drains (also called drum drips) are utilized to drain residual water and condensation from low points in dry pipe systems. These drains must be properly emptied before the onset of freezing temperatures to prevent freeze breaks.

Figure 3. Fractured chlorinated polyvinyl chloride (CPVC) sprinkler pipe

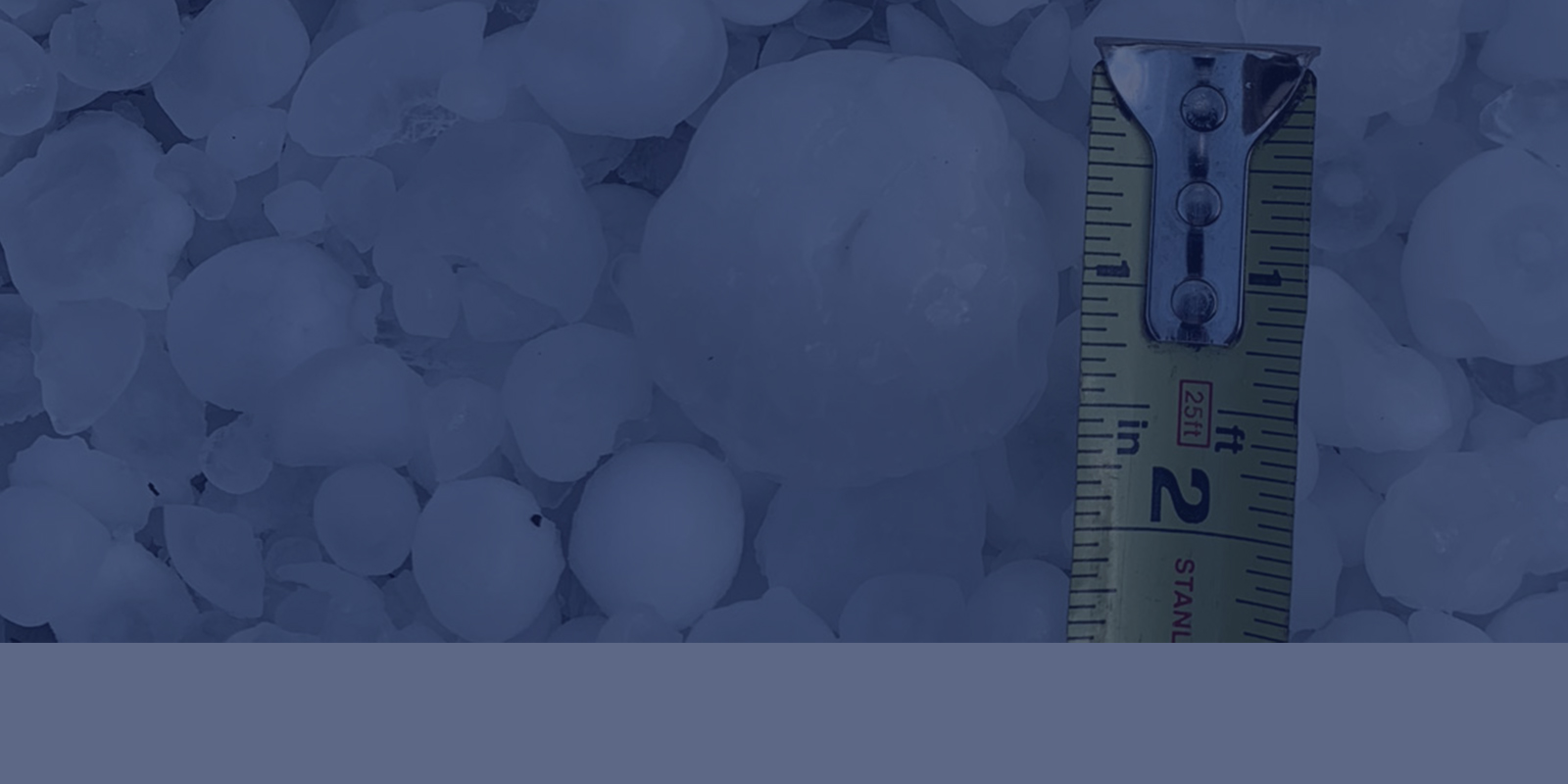

In February 2021, Winter Storm Uri brought unusually freezing temperatures to many parts of the southern United States. Many buildings experienced freezing temperatures for several straight days in addition to power outages, as natural gas and electrical distribution systems were overwhelmed by the severe weather conditions. Without power and/or gas, buildings could not reliably maintain space conditioning. Further, air compressors for dry pipe systems could not maintain the air pressure within the system required to keep dry pipe valves closed, thus filling the systems with water while the pipes were exposed to well-below-freezing temperatures. This combination of conditions caused widespread damage to fire sprinkler systems, resulting in severe leaks upon thawing and related damage to building finishes and contents in the vicinity of the pipe damage. Nelson’s mechanical engineers have evaluated hundreds fire sprinkler systems related to Winter Storm Uri and other freezing weather events, and are ready to assist with evaluations of fire sprinkler systems affected by any peril.