When the forces applied to a structure exceed the structure’s capacity, a failure will occur. Structural failures are often caused by natural perils, design and construction deficiencies, deferred maintenance, and misuse. Nelson’s structural, architectural, and civil engineers specialize in assessing the cause and extent of damage and defects to many types of structural systems; including buildings, bridges, towers, tanks, racks, retaining walls, pavements, and components thereof. These professionals also develop solutions to remediate, repair, and strengthen damaged and defective structural systems.

Nelson’s engineers are experts at investigating failures due to hurricanes, tornadoes, storms, floods, fires, vibrations, impacts, explosions, earthquakes, unstable soils, and material defects.

They also assess the effects of design defects, construction defects, and improper use on the strength, serviceability, and durability of structures. Nelson’s engineers are experienced in evaluating commercial, industrial, residential, institutional, educational, healthcare, athletic, marine, infrastructure and agricultural structures, among others.

NOTABLE PROJECTS

Unintended Consequences

A roof collapse occurred during normal business hours at a North Texas car dealership during a spring rainstorm while staff and customers were inside. Thankfully, no one was injured and Nelson’s experts arrived onsite rapidly to begin evaluating the building and determining the cause(s) and extent of the collapse. During the following weeks, Nelson’s experts carefully sifted through the debris, making observations, theorizing, and testing hypothesizes with detailed meteorological and structural models. Ultimately, Nelson’s experts determined that the cause of the collapse was a recent, yet deficient, roof overlay where the primary and secondary (emergency) roof drainage system capacities were severely reduced (or abandoned altogether,) causing rainwater to build up on the roof surface and overloading the structural framing to the point of failure.

Warehouse Roof Collapse

The roof of a commercial warehouse building was redesigned and remodeled from a sawtooth-type roof covered with metal panels and roof gutters at valleys, to a single-ply membrane roof system with crickets and internal primary and secondary drains. Shortly after the roof remodel was completed, a portion of the roof collapsed during a heavy rainstorm event. During an initial evaluation of the building, Nelson found that piping for the secondary roof drains tied into the piping system for the primary roof drains. Nelson’s analysis discovered that the primary drainage piping didn’t have sufficient code-required capacity for both the primary and secondary drains. As a result of inadequate drainage pipe capacity, water was unable to properly drain from the roof, causing a roof ponding condition, which resulted in collapse of the roof. Additionally, loading from ponded water caused some of the roof framing at and adjacent to the collapsed area to deflect/deform downward such that the concrete tilt-up walls supporting the roof framing were pulled inward, resulting in permanent lateral displacement of and fractures in the tilt-up walls.

Bada Boom

On a hot summer evening, a booming explosion rattled the residents of an exclusive North Texas neighborhood. Nelson’s team of professionals were immediately retained to evaluate the structure at and around the origin of the explosion and determine the full extent of structural damage resulting therefrom. After multiple site visits, extensive testing, and the assistance of specialized contractors to remove the interior finishes for evaluation of the underlying structural framing, Nelson’s team was able successfully identify all of the structural damage resulting from the explosion and provide recommendations for repair.

Collapsed Concrete Pipe

A concrete-lined steel wastewater pipe servicing a wastewater treatment facility had collapsed, as evidenced by a sinkhole discovered by workers at the plant at the time of collapse. Nelson was asked to evaluate the wastewater pipe and determine the cause of the reported collapse. Excavation found that the top approximately half of the pipe had collapsed while the remaining lower section of pipe remained in place. Severe corrosion was discovered at the collapsed portions of the pipe, with the greatest amount of corrosion present at the typical surface level of wastewater flow within the pipe. Additionally, there was corrosion on the exterior steel casing of the pipe. Nelson determined that conditions within the pipe were conducive to the production of hydrogen sulfide (H2S) gas, and the presence of this gas, in conjunction with corrosion of the steel pipe due to moisture within the surrounding soils, reduced the structural capacity of the pipe such that it was unable to support the soil overburden.

Fire-damaged Steel

Nelson has investigated hundreds of buildings and structures that have sustained damage by fire, some resulting in localized damage, including primary framing components, and others resulting in total destruction of multiple attached buildings. Of particular interest is the behavior of steel during an intense fire, and the effects that the heat has on the steel.

Heating of steel during a fire can result in metallurgical changes that are typically temporary (limited to the duration of the fire); however, some may be permanent. Steel behavior at elevated temperatures is primarily dependent on end restraint, support, and bracing conditions. Steel expansion is temperature-dependent and unrestrained steel members will elongate as the material temperature increases. Fully restrained connections will cause temperature-dependent axial forces to develop in attached members as the temperature increases, which can result in buckling and deformation of the members.

Hydrostatic Pressure

Nelson was asked to investigate distress to the lower level of a parking garage, which reportedly occurred as a result of a heavy rainstorm. From its investigation, Nelson determined that the localized fractures and upheaval of the lower-level garage slab were the result of hydrostatic pressure from the accumulated runoff and a below-slab breach in the storm drain piping network. During rainstorms, a building’s stormwater drainage system, inclusive of components such as area drains, scuppers, leaders, and storm drain piping, is intended to safely convey the rainwater off-of and away-from the building. Proper design of these drainage components involves sizing elements for an appropriate rainfall volume and intensity. Additionally, the stormwater drainage system must be maintained throughout its service life to provide continued functionality.

Thankful Church Roof Collapse

On a quiet Tuesday, the roof of a 52-year-old church collapsed on an empty sanctuary. Members of the congregation had observed that the ceiling of the sanctuary was sagging a couple of weeks before Christmas and then cracks in the interior wall finishes at both ends of the sanctuary were noticed on Christmas Day. A few weeks later, the two side walls of the sanctuary were reportedly leaning outward. Two months later, the roof collapsed. No weather event precipitated the collapse.

The collapsed roof trusses were generally intact; however, the masonry block walls of the structure were unreinforced except along the top course of the side walls. The two side walls toppled laterally outward in a fairly uniform manner. The reported outward leaning of the side walls and distress to interior wall finishes prior to the collapse indicated that the failure was due to prolonged, progressive failure of the central framing elements of the scissor-style roof trusses.

Ponding Failure

Nelson was engaged to evaluate the collapse of the roof system over an auto dealership. Nelson discovered during the investigation that at least one of the exisiting roof drains was covered over during reroofing, while others were blocked with debris and vegetative growth. The lack of positive drainage resulted in ponding of water on the roof, evidence of which was visible in historical aerial imagery. The ponded water overloaded of the open web truss system, and ultimately caused collapse of the roof.

MSE Retaining Wall Failure

Nelson was engaged to investigate the failure of a mechanically stabilized earth (MSE) wall system along the bank of the Ohio River. The fill material behind the wall consisted of a mixture of soil and gravel, which plugged a portion of the weep (drain) holes at the wall’s facing. Visible reinforcement strips, which protruded from the sloughed off fill, were ruptured near their ends where previously attached to the facing, with a portion of the strips exhibiting corrosion. Nelson determined that the failure was the result of long-term, progressive sliding caused by excessive lateral earth pressure and erosion attributable to improper internal and external drainage of the MSE wall system.

Spoliation

Spoliation is the destruction or alteration of evidence resulting from a party’s failure to preserve that evidence which is relevant to an investigation. Nelson was engaged to investigate the reported collapse of a riding arena, which incorporated double (i.e., 2-ply) metal plate connected wood scissor trusses, each 68 feet in length. Upon arrival at the site, it was immediately noticed that the collapse site had been cleared. Further investigation revealed that the wood truss components, or portions thereof, had been put to use to service the property by other means, including fuel for the wood-fired heating system and a lean-to shed addition at one of the barns. Due to this widespread spoliation, Nelson was unable to proceed with what would have otherwise been a routine collapse investigation. However, in some situations of less egregious spoliation, an investigation may proceed using salvaged evidence, and the formation of conclusory opinions may or may not be feasible, depending on the level and nature of the spoliation.

Progressive Collapse

The roof of a two-story office building collapsed during a severe rainstorm. The impact from the collapsing roof progressively caused the second floor to also collapse onto the first floor slab. Nelson documented the collapse and analyzed the framing system and the roof drainage, and ultimately determined that the failure was the result of clogged primary and secondary roof drains, in combination with rainfall which exceeded the 100 year design storm for the area.

Caffeine Crash

This case involved a building which had been recently converted from a gas station into a café. A 2 inch rainfall occurred shortly after the conversion was completed, and caused a catastrophic failure of the wood-framed roof system while the café was occupied. Nelson documented the collapse scene, retained evidence, reviewed the original and retrofit construction documents, and performed rigorous structural and roof drainage analyses. Nelson’s engineers determined that the roof collapsed under a very light rain load because a larger air-conditioning unit had been placed atop the roof as part of the conversion to a food service facility. Structural upgrades were not performed to support the new air conditioning unit, and it overstressed the roof system. In this case, the rain was the “straw that broke the camel’s back.”

Oversized Load

A highway bridge collapsed while in service. The bridge was a 1940’s era reinforced concrete multi-arch superstructure supported by wide-flange steel columns. Nelson’s engineers documented the collapse and the structural elements of the bridge and analyzed the structural response to the heavy loads which were in place at the time of the collapse. Nelson determined that the bridge collapsed due to a vehicle load in excess of the rated capacity of the bridge, in concert with severe deterioration of the steel substructure.

Timber

The roof at a water park facility attached to a resort collapsed overnight under negligible environmental loads, and after ten years of service. The structure had been in use the previous day. Roof framing at the waterpark consisted of double (i.e., 2-ply) metal plate connected (MPC) wood scissor trusses, each 90 feet in length, with a corresponding single MPC piggyback truss (a.k.a., cap truss). The roof framing was supported by 18-foot tall bearing walls, which were framed with engineered wood studs. Nelson’s investigation determined the collapse was the result of inadequate installation of the required permanent lateral bracing system, and not the result of design deficiencies related to the individual truss components.

Fertilizer Plant Explosion

On April 17, 2013, an explosion at the West Fertilizer Company in West, Texas rocked the city and surrounding rural areas. The explosion left a crater 93′ wide and 10′ deep, caused 15 fatalities, and over 200 injuries. As a result of the extensive damage caused by the explosion, Nelson’s professionals evaluated numerous buildings throughout the city.

Nelson’s team published Performance of Structures Subjected to West Fertilizer Company Explosion in the proceedings of the 2015 American Society of Civil Engineers Forensics Congress. The publication presented a study of the respective performance of the evaluated buildings subjected to the explosion, particularly in relation to the distance from the explosion’s origin, and revealed solid correlations between published damage indicator data to the observed damage.

Twisters

Nelson’s rapid-response teams have evaluated hundreds of buildings following tornado events nationwide. Often working alongside emergency response personnel, Nelson’s engineers have assessed the safety of affected buildings, determined the extent of damage caused by tornadoes, and compared the same to code requirements for structural strength and stability. Nelson’s engineers have recommended remediation for some affected buildings, and suggested demolition of others which were damaged beyond the limits of economical repair.

Nelson personnel responded immediately to the sites of EF-5 tornado damage in Joplin, Missouri and Moore, Oklahoma. Nelson’s engineers also assisted in damage evaluations following the Vilonia, Arkansas EF-5 tornado; the 2014 84-tornado outbreak; and the 2011 Super Outbreak, where 360 tornadoes touched down in 21 states.

Heavy Metal

While roof collapses are not uncommon, this case was unique, as the steel joist roof framing collapsed along the entire 900 foot length of one perimeter wall. Nelson’s engineers responded immediately, documented the collapse, and analyzed the evidence to determine the cause of the failure. The failure mode was determined to be related to deficiencies in the design and manufacturing of the welds connecting the joist members, and then subsequent tearing of the steel material around the welded connections. The joists utilized in this structure were a new product to the market, and testing of the joists revealed that they were prone to this type of sudden failure.

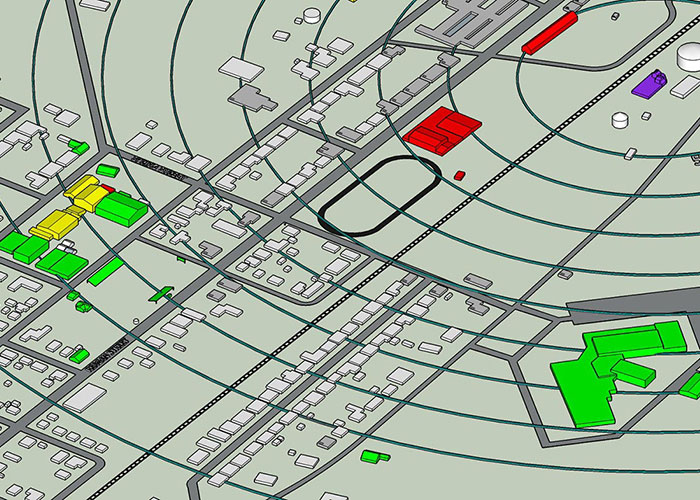

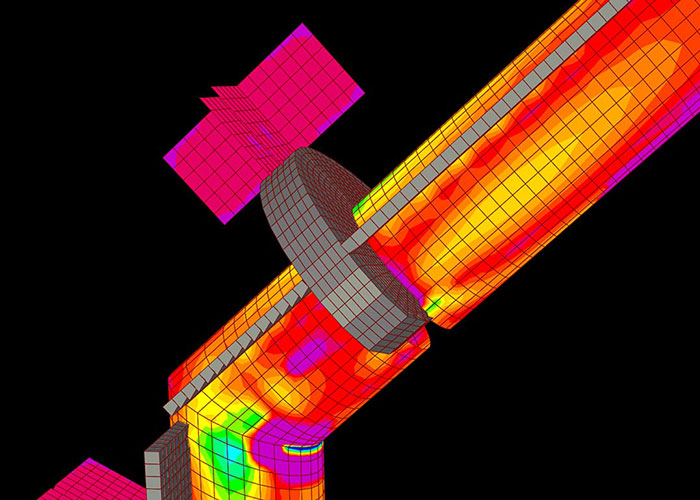

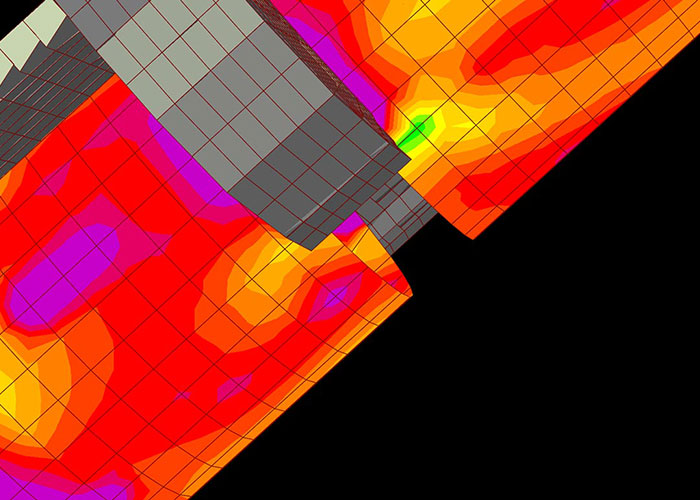

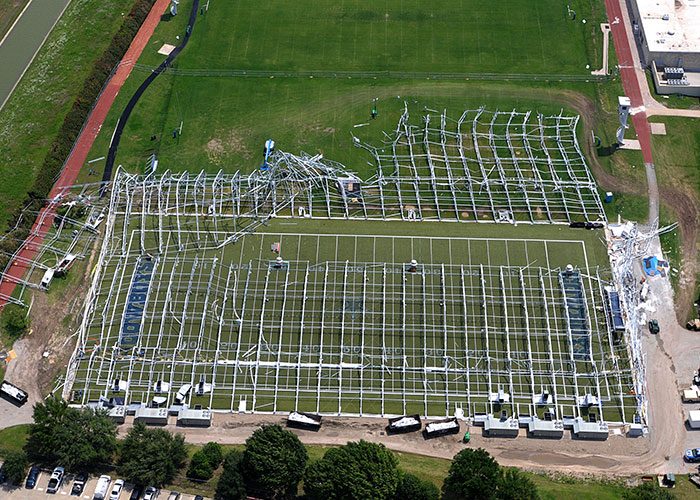

Dallas Cowboys Practice Facility

The 83,000 square foot steel-framed membrane-envelope building housed a full-size football field and observation areas; and it collapsed during a windstorm with maximum wind speeds of 55 mph. Nelson’s team of engineers responded immediately to document the collapse scene, collect evidence, and ultimately determine the cause of the failure. Nelson’s team directed the controlled dismantling of the remnants of the facility and transportation of the evidence to a secure storage facility. Nelson’s forensic analysts performed load development based on forensic meteorological data, wind/structure interaction analysis, and extensive finite-element modeling of the global structural system and solids continuum modeling of structural connections. The numerical modeling results were validated with physical evidence, and the cause of the collapse was determined to be related to deficient structural design.

Tread Lightly

A two-span pedestrian bridge which connected the second floor of a shopping mall with the adjacent parking garage collapsed. The bridge was constructed of wide-flange steel fascia girders, transverse floor beams, and concrete on corrugated steel deck. Nelson documented and analyzed the collapsed bridge, and determined that the bridge failed under its own weight due to severe long-term deterioration of the steel support framing.

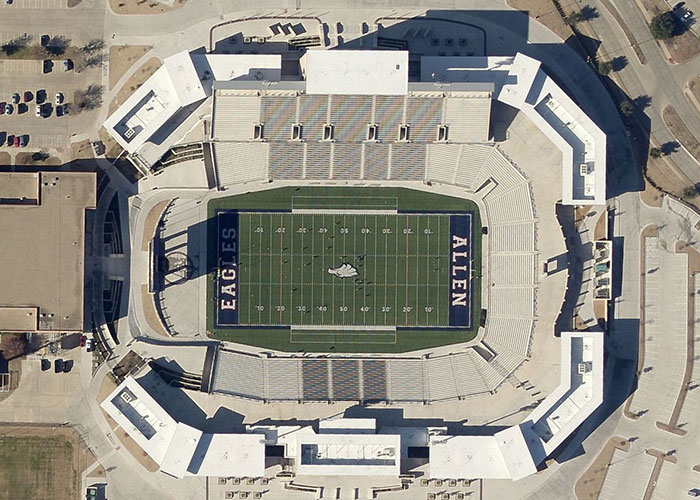

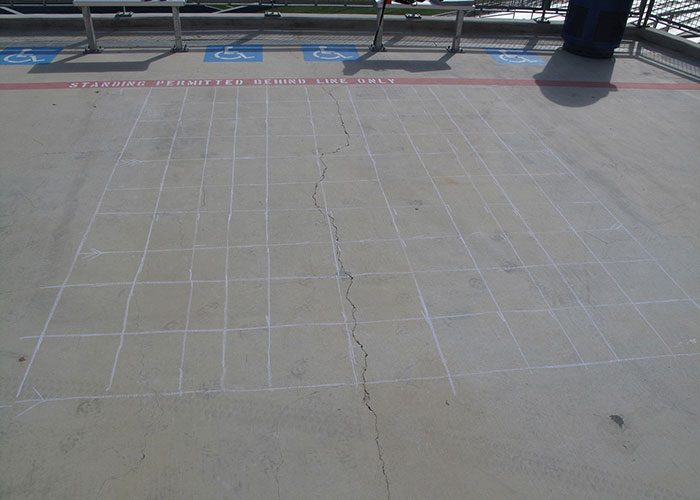

Allen Eagle Stadium

Two years after construction of the $60,000,000, 18,000 seat Eagle Stadium in Allen, Texas was completed, Nelson was retained to evaluate unusual cracking at the elevated, reinforced concrete concourse level. Upon initial review of the structural plans, Nelson identified deficiencies in the concourse level framing, and subsequently recommended a full review of the as-built construction documents for the entire stadium. Nelson’s review uncovered flaws in many of the structural load carrying elements of the stadium. Those design flaws, in concert with construction deficiencies, rendered the stadium unsuitable for occupancy, and necessitated a massive repair and strengthening effort. Nelson participated in design of the repair and strengthening solutions in close collaboration with structural design firm Datum Engineers, performed construction administration during the repair effort, and assisted with dispute resolution. The stadium reopened 14 months after its closing.